CSWIP 3.2: A Comprehensive Study Plan

Accessing CSWIP 3.2 study materials, including Level III resources, API certifications (510, 570, 653), and radiographic interpretation guides, is available via ndt.net forums.

CSWIP 3.2 certification signifies a high level of competence in welding inspection, particularly with radiographic interpretation, crucial for Senior Welding Inspector roles. Obtaining this qualification demonstrates proficiency aligned with ISO standards, though a standalone CSWIP 3.2 doesn’t fully comply. Preparation often involves accessing comprehensive study materials, with resources available through platforms like ndt.net’s forums, offering downloadable PDFs covering Level III, API 510, 570, and 653 exams alongside CSWIP content.

The certification’s practical component assesses inspection skills on both light and dense metallic materials. Successful candidates demonstrate a thorough understanding of welding processes, NDT methods, and acceptance criteria. The supplementary radiographic interpreter examination is vital for achieving the full 3.2.2 Senior Welding Inspector designation.

Overview of the Senior Welding Inspector Role

Senior Welding Inspectors, often holding CSWIP 3.2 certification with radiographic interpretation (3.2.2), are responsible for ensuring the integrity and quality of welded structures. Their duties encompass interpreting radiographic films, assessing defects, and verifying compliance with relevant standards. Accessing study materials, including those found on ndt.net forums – offering PDFs for Level III, API 510/570/653, and CSWIP – is crucial for preparation.

This role demands expertise in various NDT methods and a deep understanding of welding metallurgy. Inspectors must navigate acceptance criteria and demonstrate proficiency in both light and dense material inspection, as evaluated during the practical exam. Maintaining current knowledge of industry trends and regulatory changes is also essential.

Understanding the CSWIP 3.2 Exam

Preparation involves mastering radiographic interpretation, alongside core competencies; downloadable study materials, including API resources, are available through ndt.net forums for effective study.

Exam Structure and Format

The CSWIP 3.2 exam is a rigorous assessment of a Senior Welding Inspector’s knowledge and practical skills. It comprises both written and practical components, demanding thorough preparation. The written portion tests understanding of welding processes, metallurgy, NDT methods, and acceptance criteria. Crucially, the 3.2.2 supplementary exam focuses intensely on radiographic interpretation, a key skill for this certification level.

Candidates should anticipate questions covering light and dense material inspection during the practical exam, mirroring real-world scenarios. Resources like ndt.net forums offer valuable insights and downloadable study materials, including those aligned with API certifications (510, 570, 653), aiding comprehensive preparation. Success requires not only theoretical knowledge but also the ability to apply it effectively in practical inspection situations.

Syllabus Breakdown: Core Competencies

The CSWIP 3.2 syllabus centers on advanced welding inspection principles. Core competencies include a deep understanding of welding metallurgy, diverse welding processes, and comprehensive knowledge of both destructive and non-destructive testing (NDT) methodologies. A significant portion focuses on interpreting welding standards and applying acceptance criteria accurately.

Specifically, the 3.2.2 component demands mastery of radiographic interpretation, encompassing film types, image quality factors, and defect recognition. Supplementary study materials, often found through resources like ndt.net, and those aligning with API certifications (510, 570, 653), are vital. Proficiency in ISO compliance is also essential, as the certification doesn’t fully comply with all ISO standards, requiring nuanced understanding.

Radiographic Interpretation Component (3.2.2)

The 3.2.2 module intensely focuses on radiographic film interpretation, demanding a thorough grasp of various film types and their characteristics. Understanding image quality factors is paramount for accurate defect assessment. Successful candidates must expertly identify common radiographic indications, differentiating between acceptable variations and critical flaws.

Preparation necessitates dedicated study of radiographic techniques and a practical understanding of light and dense material inspection. Resources, including supplementary examination materials accessible via platforms like ndt.net, are crucial. Mastering this component is key to achieving the Senior Welding Inspector qualification, as it’s a distinct cycle within the certification process.

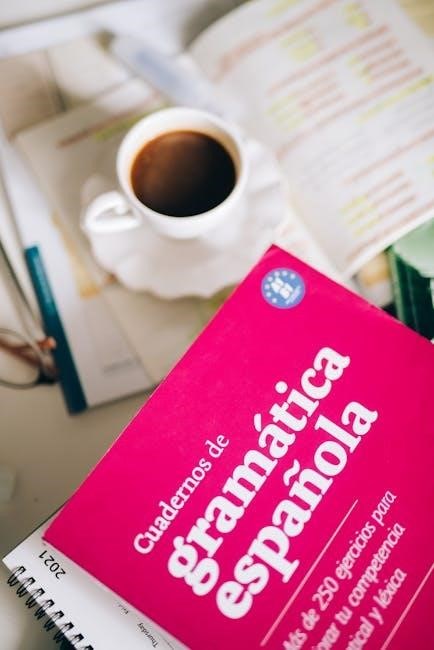

Essential Study Materials

Comprehensive preparation relies on official CSWIP guides, recommended textbooks, and resources found on ndt.net forums, including downloadable PDF study materials.

Official CSWIP 3.2 Study Guides

Securing official CSWIP 3.2 study guides is paramount for thorough exam preparation. These guides, available through the British Institute of Non-Destructive Testing (BINDT), provide a foundational understanding of the syllabus and expected knowledge base. While direct PDF access to the complete official guide isn’t always freely available, BINDT offers various learning resources;

Supplementing these official materials with resources discovered on platforms like ndt.net can prove beneficial. Forum discussions often point to supplementary materials and shared experiences from candidates who have successfully completed the certification. Remember that relying solely on unofficial PDFs is risky; prioritize the official BINDT resources for accuracy and completeness. The radiographic interpreter supplementary examination is crucial for the 3.2.2 Senior Welding Inspector qualification.

Recommended Textbooks and Resources

Beyond official guides, several textbooks bolster CSWIP 3;2 preparation. Resources covering welding metallurgy, NDT methods (particularly radiographic interpretation), and relevant ISO standards are essential. While a single definitive textbook doesn’t exist, materials supporting API 510, 570, and 653 certifications – often found linked on ndt.net forums – can provide valuable cross-training.

Focus on texts detailing acceptance criteria and practical inspection techniques. Remember the practical exam covers both light and dense materials. Caution is advised regarding freely available PDF study materials; verify their source and currency. Prioritize reputable publishers and regularly updated editions to align with current industry practices and standards, ensuring a comprehensive understanding for the 3.2.2 qualification.

Online Forums and Communities (ndt.net)

The ndt.net forum serves as a crucial hub for CSWIP 3.2 candidates. Discussions frequently address exam preparation, sharing of study materials – including PDFs for Level III, CSWIP 3.1, and API certifications (510, 570, 653) – and clarification of complex concepts. Users often post links to resources and offer advice based on their experiences.

Active participation allows for collaborative learning and access to a wealth of practical insights. Be mindful of material validity; cross-reference information with official sources. The forum is particularly valuable for understanding the radiographic interpretation component (3.2.2) and navigating the practical examination, covering light and dense materials. Remember to contribute and engage respectfully within the community.

Availability of PDF Study Materials

Numerous PDF study materials for CSWIP 3.2 are circulated online, often referenced within the ndt.net forum. These resources encompass Level III materials, alongside preparation guides for related API certifications like 510, 570, and 653. However, verifying the currency and accuracy of these PDFs is paramount, as standards evolve.

While convenient, unofficial PDFs should supplement, not replace, official CSWIP study guides. Focus on materials covering radiographic interpretation techniques, common indications, and acceptance criteria. Be cautious of sources offering “free” complete answer papers, as these may be outdated or inaccurate. Prioritize legitimate resources to ensure thorough preparation for both theoretical and practical components of the examination.

Key Topics for Effective Preparation

Mastering welding processes, NDT methods, inspection techniques, and acceptance criteria are crucial, alongside focused study of radiographic interpretation for CSWIP 3.2 success.

Welding Processes and Metallurgy

A thorough understanding of diverse welding processes – such as SMAW, GMAW, GTAW, and SAW – is fundamental for CSWIP 3.2 candidates. This includes detailed knowledge of their applications, advantages, and disadvantages. Equally important is a robust grasp of metallurgy, specifically the impact of welding on material properties.

Focus on heat-affected zones, phase transformations, and potential defects like porosity, inclusions, and cracks. Candidates should be able to correlate welding parameters with resulting metallurgical structures and mechanical properties. Resources available through ndt.net forums and supplementary materials can aid in mastering these complex concepts, preparing you for both theoretical and practical examination components. Understanding material specifications and their weldability is also key.

Destructive and Non-Destructive Testing (NDT) Methods

CSWIP 3.2 demands comprehensive knowledge of both destructive and non-destructive testing (NDT) methods. Destructive testing, including tensile, bend, and impact tests, reveals material properties but compromises the component. NDT, conversely, evaluates without causing damage, utilizing techniques like visual testing, radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), and dye penetrant testing (PT).

Mastering RT is crucial, given the 3.2.2 radiographic interpretation component. Resources on ndt.net and associated study materials provide detailed insights into each NDT method’s principles, applications, advantages, limitations, and interpretation of results. Understanding acceptance criteria based on relevant standards is paramount for effective welding inspection and certification success.

Welding Inspection Techniques

Effective welding inspection requires a blend of visual acuity, technical knowledge, and adherence to standards. Techniques encompass visual inspection (VT) for surface defects, dimensional checks, and weld profile assessment. Radiographic testing (RT), a core component of CSWIP 3.2.2, reveals internal flaws. Ultrasonic testing (UT) provides volumetric inspection capabilities, while magnetic particle (MT) and dye penetrant (PT) detect surface and near-surface discontinuities.

Study materials accessible through platforms like ndt.net emphasize practical application. Understanding weld mapping, sequencing, and the impact of welding parameters on defect formation is vital. Proficiency in interpreting inspection results against acceptance criteria, as defined in codes and standards, is essential for a competent Senior Welding Inspector.

Acceptance Criteria and Standards

Mastering acceptance criteria is paramount for CSWIP 3.2 certified inspectors. Standards like ISO 5817 (RT), ISO 17637 (UT), and ASME Section IX dictate permissible flaw sizes and distributions. Understanding these standards, alongside client-specific requirements, ensures weld integrity and structural safety. Resources available via ndt.net forums and downloadable study materials often include detailed breakdowns of acceptance levels (A, B, C, D) and corresponding defect evaluations.

CSWIP 3.2 emphasizes the ability to apply these criteria consistently and accurately. The practical examination assesses this skill, requiring candidates to evaluate radiographic images and determine compliance. Knowledge of relevant codes and standards is non-negotiable for successful certification.

Focus on Radiographic Interpretation

The CSWIP 3.2.2 supplementary exam focuses on radiographic interpretation; downloadable study materials and ndt.net resources aid in mastering this crucial skill.

Radiographic Film Types and Characteristics

Understanding radiographic film is paramount for CSWIP 3.2.2 certification, demanding knowledge of various types and their unique characteristics. Resources available through ndt.net forums and downloadable study materials cover film speed, contrast, and graininess. These factors directly impact image quality and defect detectability.

Specifically, candidates must differentiate between various film sensitivities (slow, medium, fast) and their applications. Knowledge of film processing techniques – development, fixing, washing, and drying – is also crucial, as improper processing can introduce artifacts mimicking defects. Mastering these concepts, aided by accessible PDF study materials, is essential for successful radiographic interpretation and exam performance;

Image Quality Factors

Achieving optimal radiographic image quality requires a thorough understanding of influencing factors. CSWIP 3.2.2 candidates must grasp the interplay between source distance, exposure time, material thickness, and film type. Downloadable study materials, often shared on platforms like ndt;net, detail these relationships.

Key factors include geometric unsharpness, caused by finite source size and object-to-film distance, and motion blur, resulting from movement during exposure. Contrast and resolution are also vital; higher contrast enhances defect visibility, while improved resolution allows for smaller flaw detection. Mastering these concepts, accessible through readily available PDF resources, is crucial for accurate radiographic interpretation and successful examination outcomes.

Radiographic Interpretation Techniques

Effective radiographic interpretation, central to CSWIP 3.2.2 certification, demands systematic analysis. Study materials, including those found via ndt.net forums and downloadable PDFs, emphasize a structured approach: density variations, shape, size, and location of indications. Understanding image quality factors is paramount for accurate assessment;

Techniques involve differentiating between real and spurious indications, recognizing various defect types (porosity, slag inclusions, cracks), and applying acceptance criteria. Proficiency requires consistent practice with sample radiographs. Resources often highlight the importance of density comparisons and careful observation to identify subtle anomalies. Mastering these skills, aided by comprehensive study guides, is vital for reliable inspection results.

Common Radiographic Indications and Defects

CSWIP 3.2.2 preparation necessitates thorough knowledge of radiographic indications. Study materials, accessible through resources like ndt.net and downloadable PDFs, detail common defects: porosity, slag inclusions, voids, cracks, and tungsten inclusions. Understanding their radiographic appearance is crucial.

Distinguishing between these defects requires recognizing variations in shape, density, and orientation. Resources emphasize identifying linear indications (cracks), rounded indications (porosity), and irregular shapes (slag). Proper interpretation demands awareness of potential causes and their impact on weld integrity. Mastering defect recognition, aided by practical examples within study guides, is essential for accurate assessment and reporting.

Practical Examination Preparation

The practical exam assesses inspection of both light and dense metallic materials; downloadable study materials and ndt.net forums aid preparation for scenarios.

Light and Dense Material Inspection

Successfully navigating the CSWIP 3.2 practical examination necessitates proficiency in inspecting both light and dense metallic materials. This component rigorously tests a candidate’s ability to apply learned principles to real-world scenarios. Resources available online, particularly through platforms like ndt.net, offer valuable supplementary materials and forum discussions focused on practical exam preparation.

Candidates should prioritize understanding the differing techniques required for each material type, focusing on radiographic interpretation and defect recognition. Accessing downloadable study materials, including those covering Level III CSWIP and related API certifications (510, 570, 653), can significantly enhance preparedness. Thorough practice with simulated exam scenarios is crucial for building confidence and mastering the necessary skills to effectively evaluate weld quality across a spectrum of material densities.

Practical Exam Scenarios and Simulations

Effective preparation for the CSWIP 3.2 practical exam hinges on extensive exposure to realistic scenarios and simulations. Utilizing downloadable study materials, often found through resources linked on forums like ndt.net, provides a foundation for understanding common weld defects and inspection challenges. These materials frequently complement Level III CSWIP and API certification (510, 570, 653) study guides.

Candidates should actively seek opportunities to practice interpreting radiographic images and applying acceptance criteria to diverse weld configurations. Simulating exam conditions – including time constraints and material variations – is vital. Mastering the practical aspects, alongside theoretical knowledge, ensures a comprehensive understanding and boosts confidence when facing the actual examination, particularly concerning the radiographic interpreter supplementary assessment.

ISO Compliance Considerations

Understanding ISO standards is crucial for CSWIP 3.2 certified inspectors, as the certification itself doesn’t fully comply with all ISO requirements. Study materials, accessible through platforms like ndt.net and supplementary resources for API certifications (510, 570, 653), should emphasize the nuances of ISO standards related to welding inspection and non-destructive testing.

Inspectors must be aware of how ISO standards influence acceptance criteria and reporting procedures. Thorough preparation, utilizing downloadable resources and Level III CSWIP guides, ensures adherence to internationally recognized quality control protocols. This knowledge is particularly important when interpreting radiographic images and evaluating weld integrity, bridging the gap between CSWIP certification and broader industry expectations.

Exam Strategies and Tips

Effective time management and understanding potential exam pitfalls are key; utilize study materials from ndt.net and API resources for optimal preparation.

Time Management During the Exam

Prioritize questions strategically during the CSWIP 3.2 exam, allocating time based on point value and personal confidence. Begin with questions you can answer quickly and accurately to build momentum and secure easy marks. Don’t dwell excessively on challenging questions; mark them for review if time permits.

Utilize available resources, like practice exams found through ndt.net forums, to simulate exam conditions and refine your pacing. Familiarize yourself with the exam structure and format beforehand. Remember the radiographic interpretation component (3.2.2) requires focused attention.

Effective time management isn’t just about speed; it’s about efficient allocation of effort. Review marked questions thoroughly, ensuring all answers are carefully considered before submission. A well-planned approach maximizes your chances of success.

Effective Question Answering Techniques

Master the art of dissecting CSWIP 3.2 questions, identifying keywords and understanding the core requirement. Eliminate obviously incorrect answers first, narrowing down your choices. Pay close attention to negative phrasing (“not,” “except”) as these often trick candidates.

Leverage study materials, including those shared on ndt.net forums, to understand the reasoning behind correct answers. Practice interpreting radiographic images (3.2.2) and applying acceptance criteria. Focus on understanding why an answer is right, not just memorizing it.

Always read the entire question and all answer options before selecting your response. Avoid making assumptions; base your answer solely on the information provided. A systematic approach, honed through practice, will significantly improve your accuracy.

Understanding Common Exam Pitfalls

Candidates often stumble on CSWIP 3.2 exams due to overconfidence or incomplete understanding of NDT methods. A frequent pitfall is misinterpreting radiographic indications, failing to differentiate between harmless anomalies and critical defects – a key focus of 3.2.2.

Beware of questions testing ISO compliance, as the exam assesses practical application. Many struggle with acceptance criteria, particularly when dealing with light and dense materials during the practical examination. Resources on ndt.net can help clarify these points.

Avoid rushing; time management is crucial. Don’t get bogged down on difficult questions – flag them and return later. Thorough preparation using available study materials is the best defense against these common pitfalls.

Resources for API Certification Alignment

Leverage API 510, 570, and 653 study materials to supplement CSWIP 3.2 preparation, as resources are often available together on platforms like ndt.net.

Relationship between CSWIP and API Certifications (510, 570, 653)

The CSWIP 3.2 Senior Welding Inspector certification demonstrates comprehensive knowledge of welding inspection, while API certifications (510 – Pressure Vessel Inspection, 570 – Piping Inspection, and 653 – Tank Inspection) focus on specific equipment. Often, individuals pursuing CSWIP 3.2 also hold or aim for relevant API credentials, creating a synergistic skillset.

Study materials for these certifications frequently overlap, particularly in NDT methods and acceptance criteria. Resources available on platforms like ndt.net often bundle study guides for Level III, CSWIP 3.1/3.2, and various API exams. This interconnectedness allows candidates to efficiently prepare for multiple certifications simultaneously, maximizing their expertise in the field of asset integrity and inspection.

Understanding the nuances of both CSWIP and API standards provides a well-rounded foundation for a successful career in welding and non-destructive testing.

Leveraging API Study Materials for CSWIP Preparation

API study materials, particularly those for API 510, 570, and 653, can significantly bolster CSWIP 3.2 preparation, especially concerning practical application of inspection techniques and acceptance criteria. The overlap in NDT principles and welding metallurgy provides a strong foundation.

Resources found on platforms like ndt.net frequently offer combined study packages for CSWIP and API certifications, streamlining the learning process. Focusing on API materials related to radiographic interpretation can directly enhance skills needed for the CSWIP 3.2.2 component.

Utilizing these supplementary resources allows candidates to reinforce core concepts and broaden their understanding of industry best practices, ultimately improving exam performance and on-the-job competency.

Staying Updated with Industry Trends

Continuous professional development is crucial; monitor changes in standards, regulations, and welding inspection advancements to maintain CSWIP 3.2 competency.

Recent Developments in Welding Inspection

The field of welding inspection is dynamically evolving, demanding continuous learning for CSWIP 3.2 certified professionals. Recent trends highlight increased reliance on automated inspection techniques, including phased array ultrasonic testing (PAUT) and advanced radiographic methods. Digital radiography (DR) and computed radiography (CR) are becoming increasingly prevalent, requiring updated skills in image interpretation.

Furthermore, the integration of artificial intelligence (AI) and machine learning (ML) into NDT processes is gaining momentum, offering potential for improved defect detection and characterization. Staying abreast of these technological advancements, alongside evolving industry standards like ISO, is vital. Resources like ndt.net forums provide valuable insights into these developments, complementing formal CSWIP 3.2 study materials and ensuring practitioners remain at the forefront of best practices.

Changes in Standards and Regulations

Keeping current with evolving standards is paramount for CSWIP 3.2 certified welding inspectors. Notably, ISO standards relating to welding and NDT are frequently updated, impacting acceptance criteria and inspection procedures. Understanding these revisions is crucial for maintaining compliance and ensuring the integrity of welded structures. The CSWIP 3.2 certification, while respected, doesn’t automatically comply with all ISO requirements, necessitating supplementary knowledge.

Accessing the latest revisions of standards, alongside utilizing resources like ndt.net forums for discussion and clarification, is essential. Study materials, including those found online, must reflect these changes. Staying informed about regulatory updates from governing bodies ensures inspectors can confidently apply best practices and navigate the complexities of modern welding inspection.